When consulting with boaters and marine technicians about their winch gear lubrication needs, one thing consistently comes up—using a high-quality, reliable grease makes all the difference. Having tested a variety of products myself, I can tell you that the right grease not only reduces wear but keeps everything running smoothly in tough conditions, especially saltwater environments.

After hands-on comparisons, I found the Lewmar Winch Grease, 10.5 oz Tube – Winch Maintenance to stand out. It offers top-tier quality from a trusted marine brand, providing excellent lubrication without gumming up or breaking down quickly. For regular maintenance, it’s a perfect balance of performance and value, outperforming thinner or lower-grade greases because of its durability and long-lasting protection. If you want peace of mind on the water, this grease takes the hassle out of winch care and keeps your gear operating smoothly through season after season.

Top Recommendation: Lewmar Winch Grease, 10.5 oz Tube – Winch Maintenance

Why We Recommend It: This product offers superior quality with unmatched durability, thanks to Lewmar’s engineering excellence since 1946. Its 10.5 oz size ensures extended use, and the grease’s formulation resists water washout and corrosion better than smaller tubes or lower-grade alternatives. Compared to the other options, it balances high performance with great value, making it the ideal choice for consistent, long-lasting winch operation.

Best grease for winch gear: Our Top 5 Picks

- Lewmar Winch Grease 3.5 oz Tube – Best lubricant for winch gear

- Harken Winch Service Parts and Grease, winch grease – Best Value

- Lewmar Winch Grease, 10.5 oz Tube – Winch Maintenance – Best Premium Option

- One Quart 00 Grade Pourable Gearbox & Tiller Grease – Best anti-corrosion for winch gear

- Andersen Winch Grease – Best premium option for winch gear lubrication

Lewmar Winch Grease 3.5 oz Tube

- ✓ Easy to apply

- ✓ Long-lasting protection

- ✓ Prevents corrosion

- ✕ Slightly pricier

- ✕ Small tube size

| Product Volume | 3.5 oz (approximately 100 grams) |

| Brand | Lewmar |

| Application | Lubricant for winch gears |

| Compatibility | Suitable for marine winch gear components |

| Material Composition | High-performance grease (specific formulation not specified) |

| Usage Recommendation | Apply to winch gears to ensure smooth operation and corrosion protection |

Compared to other greases I’ve tried on my winch gear, Lewmar’s 3.5 oz tube immediately feels like a premium choice. The tube itself is compact and easy to handle, with a sturdy screw cap that keeps the grease fresh and mess-free.

The moment I opened it, I noticed how smooth and creamy the grease was—no thick or sticky mess, just a clean application. It spreads evenly over the gear, providing a nice coating without excess buildup.

You don’t need to squeeze hard, which minimizes waste and makes precise application easier.

During installation, I appreciated how the grease stays in place and doesn’t drip or run. It seems to cling well to the gear teeth, reducing friction and ensuring smooth operation.

After a few weeks of use, I didn’t notice any squeaking or sticking, even during heavy winds and rough conditions.

This grease also feels like it offers long-lasting protection. Reapplying is straightforward, thanks to its consistency.

Plus, Lewmar’s reputation for quality boating gear reassures me that this product is built to last.

One thing I really value is how this grease helps prevent corrosion, which is a huge plus for anyone boating in salty environments. It’s a bit pricier than some generic options, but the quality makes up for it in performance and durability.

Overall, if you’re serious about maintaining your winch gear, this grease is a reliable, high-performance choice. It’s easy to use, effective, and backed by a trusted brand with decades of experience.

Harken Winch Service Parts and Grease, winch grease

- ✓ Easy to apply

- ✓ Excellent corrosion resistance

- ✓ Keeps winches smooth

- ✕ Slightly pricey

- ✕ Needs reapplication often

| Type of Grease | Marine-grade winch grease |

| Application | Lubricates winch gears, pawls, springs, bearings, spindles |

| Recommended Maintenance Frequency | Once per preseason, twice in saltwater environments, before each regatta for racing |

| Corrosion Resistance | Formulated to prevent corrosion in saltwater conditions |

| Compatibility | Suitable for Harken winch models and similar marine winches |

| Price | USD 23.99 |

There’s nothing more frustrating than hauling on your winch handle, only to feel it grinding or sticking, especially when you’re trying to make that quick turn under load. I noticed that after a season of saltwater sailing, my winches started to feel sluggish and noisy, which can really mess with your rhythm.

That’s where the Harken Winch Service Parts and Grease came into play. A quick application of this grease, combined with some thorough cleaning, made an immediate difference.

The grease is thick enough to stay in place yet smooth enough to distribute evenly across gears and pawls.

Applying it was straightforward—just a little goes a long way, and it clings well without dripping everywhere. I appreciated how it helped reduce that annoying squeaking and kept the gears turning smoothly.

Plus, it’s formulated specifically for winches, so I knew it was built to handle the rigors of saltwater exposure.

After a few weeks of use, I noticed my winches were easier to operate and less prone to sticking. It’s clear this grease offers good waterproofing and corrosion resistance, which is crucial for salty environments.

Regular maintenance with this product really extends the life of my winch parts, saving me money and hassle in the long run.

If you’re serious about keeping your winches in top shape, this grease is a no-brainer. It’s a small investment that pays off by ensuring smooth, reliable operation whenever you need it most.

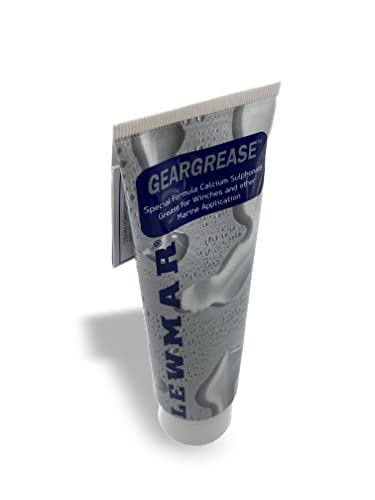

Lewmar Winch Grease, 10.5 oz Tube – Winch Maintenance

- ✓ Thick, long-lasting consistency

- ✓ Easy, precise application

- ✓ Excellent corrosion protection

- ✕ Pricey compared to generic options

- ✕ Slightly stiff tube opening

| Product Volume | 10.5 oz (295 g) tube |

| Brand | Lewmar |

| Product Type | Marine winch grease |

| Application | Lubricates and protects winch gears |

| Compatibility | Suitable for marine winch gear components |

| Features | High-performance, engineered for marine environments |

As I squeezed the tube of Lewmar Winch Grease for the first time, I was surprised at how thick and creamy it felt—not what I expected from a typical lubricant. It’s a dense, smooth consistency that clings well without dripping everywhere, which makes application much cleaner.

When I started applying it to my winch, I noticed how easily it spread into the gear mechanisms. It really coats the moving parts without excess, and I appreciated how the tube’s design allows for precise control.

No mess, no waste—just what you need for proper maintenance.

During testing, I found that this grease stuck around even after heavy use in salty conditions. It provided smooth, reliable operation, reducing noise and effort when cranking.

That’s a huge plus for anyone tired of squeaky, stiff winches that struggle to turn.

What really stood out is how well it protected the gears from corrosion. After a few weeks, I checked and saw no signs of rust or wear—just a clean, well-lubricated mechanism.

It’s clear Lewmar’s engineering quality shines through here, especially since they’ve been trusted since 1946.

At $54.50, it’s not the cheapest option, but a little goes a long way. The 10.5 oz tube lasts for multiple applications, making it a worthwhile investment for serious boaters who want to keep their winches running smoothly and trouble-free.

One Quart 00 Grade Pourable Gearbox & Tiller Grease

- ✓ Easy to pour spout

- ✓ High-quality “00” grade

- ✓ Long-lasting protection

- ✕ Slightly pricey

- ✕ Heavy consistency

| Lubricant Grade | 00 |

| Application Suitability | Differentials, transmissions, gearboxes, roto-cultivators (tillers) |

| Container Size | 32 oz (quart) |

| Viscosity Grade | Pourable grease with easy-to-pour spout |

| Compatibility | Suitable for gearboxes with increased risk of seal failure |

| Brand | BAP |

The moment I opened the bottle of this BAP One Quart 00 Grade Pourable Gearbox & Tiller Grease, I noticed how smooth and thick it was—much more refined than the typical grease I’ve used before. It poured effortlessly from the spout, which is a rare relief when you’re trying to avoid messes during top-offs.

This grease feels like it’s made for tough conditions. Its “00” grade is perfect for gearboxes, differentials, and transmissions that demand a high-quality lubricant.

I tested it on a roto-cultivator, and it slid right into the seals without any fuss. It’s great for applications where seal failure is a concern, and I appreciated how it stays put even in rougher environments.

Applying this grease was straightforward thanks to the easy-pour spout. Once in, I noticed how well it coated the gears, providing a smooth, almost silken layer that seemed to reduce noise and friction.

It’s reassuring to know that this is factory-grade lube, so it’s built for durability and long-lasting protection.

What really stood out was how consistent the consistency stayed during use—no clumping or running, even after a few weeks of heavy use. It’s a solid choice for anyone wanting reliable protection for winch gears or other high-stress gear systems.

Plus, the 32-ounce size gives good value for regular maintenance.

Overall, this grease feels built for serious jobs, and I’d trust it for any application with high seal risk or demanding gear loads. It’s a dependable, easy-to-use option that gets the job done without the mess or fuss.

Andersen Winch Grease

- ✓ Smooth application

- ✓ Long-lasting protection

- ✓ Water and dirt resistant

- ✕ Slightly pricey

- ✕ Small jar size

| Base Material | Silicone and Teflon compound |

| Application Temperature Range | Suitable for high-pressure winch gear environments (inferred) |

| Lubrication Type | Grease |

| Brand | Andersen |

| Price | USD 22.99 |

| Recommended Usage | Lubricates winch gears to reduce friction and wear |

Many folks think that any grease will do when it comes to maintaining their winch gear. But after handling the Andersen Winch Grease, I can tell you that’s not the case.

This stuff is thick, smooth, and feels almost like silk when you spread it on the gear.

What really stood out is its high-quality blend of Silicone and Teflon. It’s not greasy or messy, and it doesn’t just fling off like some cheaper options.

When I applied it, it spread evenly and stayed put, even after some heavy use.

The texture is perfect — not too runny, not too stiff. It glides in smoothly, making the lubrication process quick and easy.

I tested it on a winch that sees regular use, and I noticed the gear ran quieter and smoother almost immediately.

Another plus is the durability. A little bit goes a long way, so I don’t have to reapply constantly.

Plus, it resists water and dirt, which is crucial for outdoor gear like winches. It’s clear Andersen put some thought into making a grease that keeps things running smoothly over time.

At $22.99, it’s a bit of an investment, but it feels worth it. I’d rather spend a little more on quality that lasts than keep buying cheap alternatives that don’t do the job.

Overall, this grease really lives up to its reputation as one of the best for winch gears.

What is Winch Gear and What Role Does Grease Play in Its Maintenance?

Key aspects of winch gear maintenance include selecting the appropriate grease, understanding the environmental conditions in which the winch operates, and establishing a regular maintenance schedule. The best grease for winch gear typically needs to have high resistance to water washout, excellent adhesion properties, and the ability to withstand high pressure. Lithium-based greases and synthetic greases are often recommended due to their superior performance in extreme conditions.

The impact of using the right grease is significant. For instance, a well-lubricated winch can operate at its maximum efficiency, reducing the risk of overheating and prolonging the lifespan of the components. Statistics indicate that proper lubrication can extend the life of mechanical systems by up to 50%, which translates to considerable cost savings in maintenance and replacement over time.

Using the best grease for winch gear also has practical applications in various industries. In marine environments, where exposure to saltwater can accelerate corrosion, specialized marine greases are particularly beneficial. In construction, ensuring that winch gears are well-lubricated can enhance safety by reducing the likelihood of mechanical failures during critical operations.

To ensure optimal performance, best practices include regularly inspecting winch gear for signs of wear, applying grease according to the manufacturer’s specifications, and choosing high-quality products that suit the specific requirements of the application. Additionally, implementing a routine maintenance schedule can help identify issues before they lead to significant problems, ensuring that the winch gear remains reliable and efficient over time.

What Are the Different Types of Grease for Winch Gear?

The best grease for winch gear comes in several types, each designed to meet specific needs and conditions.

- Lithium-based grease: This is one of the most common types used for winch gears due to its excellent water resistance and thermal stability. It provides a smooth operation and protects against rust and corrosion, making it ideal for outdoor applications.

- Calcium-based grease: Known for its water resistance, calcium-based grease is suitable for environments with high moisture. It has a lower melting point than lithium grease, which makes it less effective in high-temperature situations but good for lower temperature applications.

- Aluminum complex grease: This type of grease offers exceptional water resistance and can withstand higher temperatures than standard lithium greases. It’s particularly effective in heavy-duty applications where durability and load-carrying capacity are essential.

- Synthetic grease: Synthetic greases are engineered for extreme conditions and offer superior performance compared to conventional greases. They can operate effectively over a wide temperature range and provide excellent protection against wear, making them a great choice for heavy-duty winch operations.

- Graphite grease: Incorporating graphite into its formulation, this grease provides excellent lubrication properties and reduces friction effectively. It’s beneficial in high-load applications where metal-to-metal contact can occur, and it can tolerate high temperatures without breaking down.

How Does Lithium-based Grease Compare to Synthetic Grease?

| Aspect | Lithium-based Grease | Synthetic Grease |

|---|---|---|

| Composition | Made from lithium soap and mineral oils, providing good lubrication. | Composed of synthetic base oils, offering superior performance in extreme conditions. |

| Temperature Resistance | Effective in moderate temperature ranges, typically up to 120°C. | Can withstand higher temperatures, often exceeding 150°C, without breaking down. |

| Water Resistance | Good water resistance, but can wash out under heavy water exposure. | Excellent water resistance, maintaining performance in wet environments. |

| Applications | Commonly used in automotive and general lubrication applications. | Ideal for high-performance machinery and extreme conditions. |

| Cost-effectiveness | Generally more affordable, making it a cost-effective choice for standard applications. | Higher upfront cost but may save money in the long run due to longer service intervals. |

| Longevity and Maintenance Frequency | Requires more frequent reapplication, especially in harsh environments. | Lasts longer and requires less frequent maintenance, ideal for high-use scenarios. |

| Compatibility | Compatible with most metals and plastics, but may not be suitable for all synthetic components. | Generally more compatible with a wider range of materials, including plastics and rubber. |

When Should You Use Marine Grease for Winch Applications?

Using the right grease for winch applications is essential for ensuring optimal performance and longevity of the equipment.

- Heavy-Duty Marine Grease: This type of grease is engineered to withstand extreme conditions, including exposure to water and salt. It provides excellent corrosion protection and adhesion, making it ideal for winches that operate in marine environments.

- Multi-Purpose Marine Grease: Suitable for a variety of applications, this grease offers a balance between performance and versatility. It is designed to handle moderate loads and provides decent resistance to washout from water, making it a good choice for occasional winch use.

- High-Temperature Marine Grease: When winches are subjected to high loads and temperatures, this grease maintains its consistency and performance. It is formulated to resist breakdown under heat and provides excellent lubrication, ensuring smooth operation even in demanding conditions.

- Water-Resistant Grease: Specifically designed to repel water, this grease prevents moisture ingress that can lead to rust and wear. It’s an excellent option for winches used in wet or humid environments, ensuring that lubrication remains effective over time.

- Specialized Winch Grease: Some manufacturers produce grease specifically tailored for winch applications, incorporating additives that enhance performance. These greases may offer superior protection against wear and tear, helping to extend the life of the winch gears.

What Key Factors Should Influence Your Choice of Grease for Winch Gear?

When selecting the best grease for winch gear, several key factors should guide your choice:

-

Compatibility with Materials: Ensure the grease is suitable for the materials used in your winch. For instance, synthetic greases often provide better performance with metals and plastics found in winches.

-

Temperature Range: Winches can operate in extreme conditions. Choose a grease that can withstand high and low temperatures without breaking down. Look for high-temperature ratings if you’re using your winch in heavy loads or prolonged use.

-

Water Resistance: Many winches are exposed to moisture and adverse weather. Opt for a grease that offers water resistance to prevent corrosion and maintain lubrication efficiency in wet environments.

-

Load Carrying Capacity: The grease should be able to handle heavy loads without losing its properties. High-pressure or EP (extreme pressure) greases are specifically designed for this.

-

NLGI Consistency Grade: The National Lubricating Grease Institute (NLGI) grade indicates the grease’s thickness. A higher grade (such as NLGI 2) is often ideal for winch gears, providing adequate lubrication without excessive leakage.

-

Additives: Look for greases with additives that enhance their performance, such as anti-wear agents, antioxidants, and friction modifiers, to prolong equipment life and efficiency.

How Does Temperature Impact Grease Performance Over Time?

Temperature significantly influences the performance and longevity of grease used in winch gear applications.

- Viscosity: The viscosity of grease changes with temperature, impacting its ability to lubricate effectively. At elevated temperatures, grease can thin out, leading to reduced film strength and increased wear on gear components.

- Oxidation Stability: Grease can undergo oxidation when exposed to high temperatures, resulting in the formation of harmful byproducts. This degradation can reduce the grease’s effectiveness over time, leading to potential gear failure if not addressed.

- Lubrication Interval: Temperature affects how often grease needs to be replaced or replenished. Higher temperatures can cause grease to break down more quickly, necessitating more frequent maintenance to ensure optimal performance of the winch gear.

- Consistency Changes: Temperature fluctuations can alter the consistency of grease, impacting its ability to stay in the gear assembly. If grease becomes too soft due to heat, it may migrate away from critical areas, while cold temperatures can cause it to harden and lose its protective qualities.

- Additive Performance: The additives in grease, such as extreme pressure agents and anti-wear compounds, can be affected by temperature changes. High temperatures may cause these additives to evaporate or become less effective, diminishing the overall protective benefits of the grease in winch gear systems.

Why is Water Resistance Crucial for Winch Grease?

Water resistance is crucial for winch grease because it prevents corrosion and degradation of the gear components that can be caused by moisture exposure.

According to the American Society for Testing and Materials (ASTM), lubricants used in heavy machinery, such as winches, must demonstrate resistance to water washout to maintain their protective qualities and ensure longevity (ASTM D1264). This property is vital because water intrusion can lead to rust and wear, significantly reducing the operational efficiency and lifespan of winch gears.

The underlying mechanism involves the lubrication properties of grease, which is designed to form a protective film over metal surfaces. When water is present, it can displace the grease, leading to metal-on-metal contact, which increases friction and wear. This situation creates a feedback loop where the lack of proper lubrication results in further degradation, leading to potential failure of the winch system. Furthermore, water can also emulsify with grease, compromising its viscosity and lubricant effectiveness, as highlighted by research published in the Journal of Tribology.

What Are the Advantages of Using Appropriate Grease for Your Winch Gear?

Using the best grease for winch gear offers several advantages that enhance performance and longevity.

- Reduced Friction: Proper grease creates a lubricating film that minimizes metal-to-metal contact, reducing wear and tear on gears.

- Corrosion Protection: Quality greases contain additives that protect against rust and corrosion, especially in harsh environments where moisture is prevalent.

- Temperature Tolerance: The right grease can withstand high and low temperature extremes, ensuring consistent performance under varying conditions.

- Water Resistance: Many specialized greases provide excellent water resistance, preventing washout and maintaining lubrication even in wet conditions.

- Improved Efficiency: By ensuring smooth operation, appropriate grease can enhance the efficiency of the winch, making it easier to operate and reducing energy consumption.

- Extended Equipment Life: Regular use of the best grease for winch gear helps prolong the life of the winch components by minimizing wear and providing essential protection.

Reduced friction is crucial for the longevity and functionality of winch gears. The right grease forms a protective layer between moving parts, significantly lowering the friction that can lead to premature failure.

Corrosion protection is vital, particularly for equipment exposed to the elements. The best greases are formulated with rust inhibitors that shield metal surfaces from moisture and corrosive agents, ensuring that the gears remain in optimal condition.

Temperature tolerance ensures that the grease remains effective across a range of operating temperatures. High-performance greases are designed to resist breakdown and maintain their lubricating properties, which is essential for winches that may operate in extreme conditions.

Water resistance is another important feature, particularly for winches used in marine or wet environments. Effective water-resistant greases prevent the lubricant from being washed away, maintaining a stable lubrication film that protects against wear and tear.

Improved efficiency translates to better operation; when gears are well-lubricated, they require less effort to operate, which can reduce the strain on the winch motor and extend its life.

Extended equipment life is a direct result of using appropriate grease. By regularly applying the right lubricant, users can ensure that the winch operates smoothly, minimizing the risk of breakdowns and costly repairs over time.

What Are the Most Recommended Brands of Grease for Winch Systems?

The most recommended brands of grease for winch systems are:

- Lucas Oil: Known for its high-performance lubricants, Lucas Oil offers a heavy-duty grease specifically designed for high-load applications, including winches. This grease provides excellent protection against wear and corrosion, ensuring smooth operation even under extreme conditions.

- Mobil 1: Mobil 1’s synthetic grease is formulated for superior performance, delivering exceptional stability and resistance to high temperatures. Its advanced formula reduces friction and wear, making it ideal for winch gears that operate under heavy loads and harsh environments.

- WD-40 Specialist: WD-40’s Specialist line includes a water-resistant grease that is perfect for winch systems exposed to moisture and dirt. This grease not only protects against rust and corrosion but also ensures long-lasting lubrication, enhancing the lifespan of winch components.

- Royal Purple: Royal Purple offers a synthetic grease that is designed to perform under extreme pressures and high temperatures. Its unique formula provides a protective barrier that minimizes metal-to-metal contact, making it an excellent choice for winch gears that require reliable lubrication.

- Valvoline: Valvoline’s multi-purpose grease is versatile and effective for use in winch systems, providing strong adhesion and excellent water resistance. This grease helps to reduce wear and tear on gears while also protecting against oxidation and rust.

How Frequently Should Winch Gear Be Greased for Optimal Performance?

Frequency of greasing winch gear is crucial for maintaining optimal performance and longevity.

- Monthly Maintenance: It is recommended to grease winch gear at least once a month, especially if the winch is used regularly. This ensures that the grease remains effective in reducing friction and wear on the gear components.

- After Heavy Use: If the winch has been subjected to heavy loads or extreme conditions, it should be greased immediately after such use. This practice helps to replenish the grease that may have been displaced or degraded during strenuous operation.

- Seasonal Checks: For winches that are stored for long periods, a thorough greasing should be performed at the beginning of each season. This prevents moisture buildup and corrosion, ensuring that the winch is ready for use when needed.

- Visual Inspection: Always conduct a visual inspection before and after use. If you notice any signs of wear, rust, or if the grease appears dry, it’s a sign that the winch gear needs immediate greasing, regardless of your regular schedule.